*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company – Copeland. Though our name has changed, we are building on more than a century of HVACR innovation and industry leadership, and Copeland continues to offer the same products, industry stewardship, and learning opportunities you’ve grown to trust. Information found on this webpage posted before June 1, 2023 may contain our old name or branding, but you can be at ease knowing it was created with the knowledge and expertise of Copeland.

According to the Centers for Disease Control and Prevention (CDC), every year an estimated 1 in 6 Americans (i.e., 48 million people) get sick, 128,000 are hospitalized, and 3,000 die from eating contaminated food. To help prevent food poisoning and improve awareness of food safety best practices, the CDC has designated September as National Food Safety Education Month. For Emerson’s cold chain business, improving the quality and safety of food throughout the supply chain is a core principle. Among the many ways we are helping stakeholders fulfill this mission is through a focus on cold chain visibility technologies designed to monitor and track food conditions along its journey to consumers.

Effective cold chain visibility is a goal shared by nearly everyone actively involved with or impacted by the food supply chain. Recently, the Food and Drug Administration (FDA) announced a new initiative called the New Era of Smarter Food Safety Blueprint, of which traceability is a key component. Designed to build upon the FDA’s Food Safety Modernization Act (FSMA), it outlines a path forward using science and risk-based standards to help ensure food safety and prevent foodborne illnesses. With respect to traceability, the blueprint seeks to utilize modern technology to provide visibility of food from farm to table and rapidly trace contaminations to their source locations.

Temperature control and visibility technologies

Achieving precise temperature control during staging, shipping and storage is the backbone of Emerson’s strategies for helping our customers promote and achieve food safety and quality. Our products and services are designed to help stakeholders in each segment of the food cold chain implement their unique cold storage best practices and quality control methods — from proper container and facility insulation to reliable refrigeration strategies — and maintain the tightest possible temperature ranges.

Enabling visibility into food’s journey throughout the supply chain is a critical component of ensuring proper temperature control. This means our customers must have the ability to track and monitor food’s condition throughout the journey to the point of sale.

To that end, we provide refrigeration monitoring solutions that help growers, producers, shippers, restaurants and food retailers keep food within ideal temperature ranges. Throughout multiple steps of cold chain custody, our real-time monitoring devices and tracking infrastructures are helping stakeholders automate the processes of recording and documenting key data points related to food conditions, including: location, temperature, humidity, vibration and security. By leveraging these products and services, stakeholders can better use information to support their food quality and safety programs.

And since we work with multiple stakeholders, we’re better able to help facilitate information sharing and wider cold chain visibility, thereby limiting the potential for disputes while keeping the focus on preventing food safety and quality issues.

Participation with industry workgroups

Our dedication to driving food safety and quality initiatives is further demonstrated through our participation in and support of leading industry initiatives and organizations, including: the Produce Traceability Initiative (PTI), Produce Marketing Association, United Fresh Produce Association, and the Institute of Food Technologists (IFT) Global Food Traceability Center. Collectively, we share the common goal of increased cold chain visibility and traceability to promote food safety and minimize global food waste.

These are all part of our efforts to further empower the cold chain by providing more actionable data for our customers and the industry. Today, our customers utilize a variety of enterprise resource planning (ERP), transportation management systems (TMS) and other information technology (IT) architectures within their businesses, and we’ve designed our devices and data formats with the flexibility to integrate with a variety of system infrastructures — all of which further promotes visibility and information sharing in the supply chain.

Achieving industry-wide visibility will require participation from all stakeholders along the chain of custody. It’s estimated that of produce shipped in the U.S. have been applied with standardized PTI case labels. Emerson encourages all growers to participate in this and other traceability initiatives. As an industry, we must help all stakeholders understand the value of capturing cold chain data and leveraging available tools and standards.

Six Ways to Reduce Food Waste by Tracking the Supply Chain

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...

Protect Valuable Shipments in High-Crime Areas

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...

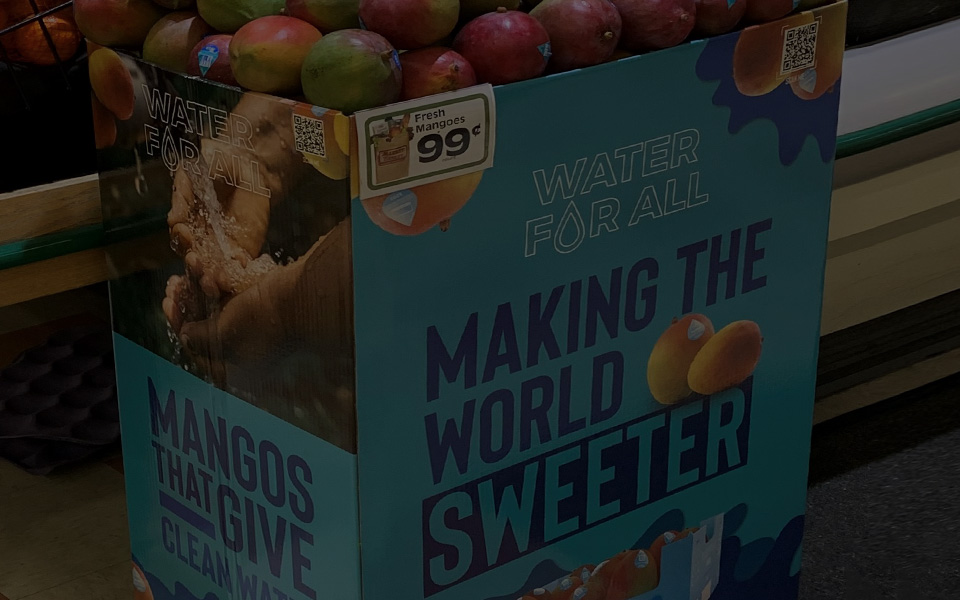

Real-time Tracking Protects Valuable Mango Cargo

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...