*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company – Copeland. Though our name has changed, we are building on more than a century of HVACR innovation and industry leadership, and Copeland continues to offer the same products, industry stewardship, and learning opportunities you’ve grown to trust. Information found on this webpage posted before June 1, 2023 may contain our old name or branding, but you can be at ease knowing it was created with the knowledge and expertise of Copeland.

Every year, the Centers for Disease Control and Prevention (CDC) designates September as National Food Safety Education Month. Their goals are to raise awareness about how to prevent food poisoning and educate the population on best practices for keeping food safe. At Emerson, we’re committed to protecting and preserving food safety throughout the various links within the food cold chain. To help in the CDC’s efforts to raise awareness, we would like to highlight some of the key areas where our cold chain tools and technologies are playing integral roles in this important mission.

Ensuring a safe food supply chain is essential for supporting human health and well-being. Supermarkets, restaurants and convenience store (C-store) sectors rely on a safe and effective food cold chain for their reputations. Consumers place food safety and quality among the most important factors when selecting a location in which to dine or shop.

The emergence of the COVID-19 pandemic has brought more public awareness to the topics of food safety, handling standards and best practices. Not surprisingly, the CDC has reported a lower rate of foodborne illness outbreaks since the beginning of the pandemic — likely attributable to the renewed emphases on proper hand washing, hygiene and surface sanitation procedures. But to achieve comprehensive food safety, it’s also important to combine safe handling protocols with robust temperature management during the transportation, cold storage and preparation phases of the food cold chain.

Let’s look at some of the ways Emerson can help to monitor temperatures during these key steps.

Harvesting and processing

The freshness and safety of perishable produce and proteins can be protected by controlling temperatures via flash cooling/freezing, temporary staging in storage coolers, and pre-cooling shipping containers. Emerson provides pulp temperature-probing devices to measure internal product temperatures during the staging and loading processes. Our real-time temperature monitoring and tracking devices can be placed inside a shipping container to provide location, temperatures and other environmental conditions of in-transit perishable shipments.

Transportation

The cold chain journey can last anywhere from days to weeks — by truck, sea and/or air — and shippers should be able to ensure an unbroken chain of temperature certainty throughout. Transport containers must be equipped to maintain strict temperatures and provide visibility to internal conditions. Emerson’s field-tested compression technologies are built to withstand the rigors of the road to help stakeholders keep transport refrigeration systems at specified temperature ranges. Our complete line of temperature monitoring, logging and tracking devices — combined with our cloud-based software portal — enables live remote monitoring and alert notifications based on user-defined parameters.

Cold storage distribution centers

Upon receipt at cold storage facilities, quality assurance (QA) personnel must inspect product conditions according to their Hazardous Analysis and Critical Control Points (HACCP) and/or Hazard Analysis and Risk-based Preventative Controls (HARPC) plans. Typically, this process starts by taking pulp temperatures and reviewing trip data from Emerson’s logging and tracking devices to validate that product was held at proper temperatures throughout the journey. After inspection, handlers must promptly transfer perishable cargo into a designated cold storage temperature zone.

Within these cold storage facilities, Emerson’s compression and refrigeration technologies help operators to establish and maintain proper temperatures in various cold storage zones. Our robust facility monitoring solutions help operators to remotely oversee conditions, ensure proper temperatures, and automatically record temperatures for use in HACCP reporting.

Grocery stores

Store operators take ownership of food quality and safety when perishable shipments are unloaded in supermarkets. This starts by checking pulp temperatures and trip data logs and continues with the prompt transfer of perishables into designated cold storage coolers or freezers. Once in cold storage, Emerson’s Lumity™ E3 supervisory control platform helps retailers to monitor perishable temperatures and optimize food quality.

For decades, the supermarket industry has relied on Copeland™ compression and refrigeration technologies as the collective foundation for their cold storage capabilities. Today, we’re developing sustainable refrigeration solutions with variable-capacity modulation to improve reliability, temperature precision and energy efficiencies in a variety of refrigeration architectures.

Restaurants

Restaurants assume responsibility for both the cold storage of perishable products as well as the safety concerns associated with food preparation. Staff must be trained in safe cooking best practices, such as those provided by the National Restaurant Association’s ServSafe® certification course. Cook-and-hold procedures should also follow established HACCP/HARPC plans, with a dual focus on the prevention of bacterial growth and maximizing food quality/safety.

Emerson provides a wide range of technologies to automate data collection and reporting necessary to implement best practices and meet local health inspection requirements:

-

- Probing devices for checking internal temperatures

- Pocket-held thermometers

- Thermocouple probes to capture a variety of temperatures (air, surface and internal)

- Thermometers for hot- and cold-side refrigeration and holding cabinets

To learn more about how Emerson is helping to protect food quality and safety throughout the food cold chain, please view this infographic.

Six Ways to Reduce Food Waste by Tracking the Supply Chain

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...

Protect Valuable Shipments in High-Crime Areas

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...

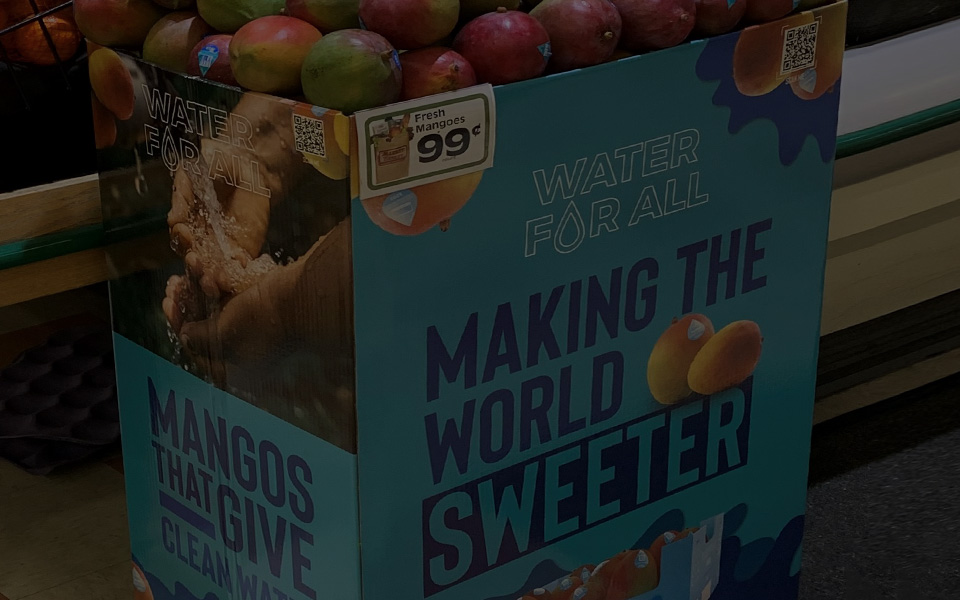

Real-time Tracking Protects Valuable Mango Cargo

*On June 1, 2023 Emerson’s Climate Technologies business became a new standalone company –...